ACES defines 10- and 12-bit encodings, used on-set only, to pass gradable imagery around the set. These are not 16-bit float encodings of the ACES image, but are lower-bit-depth "proxy" images, termed "ACESproxy" images. The 10-bit on-set encoding is called ACESproxy10; the 12-bit encoding is called ACESproxy12.

Current ARRI cameras do not have a way of directly producing an ACESproxy monitoring signal, but it is still possible to monitor in ACESproxy with the appropriate downstream hardware using an external device that can convert Log C to ACESproxy and apply the ACES transforms appropriate for an on-set display. Mechanisms to do this type of monitoring (possibly including grading of ACESproxy data with ASC CDL) include:

- Using a node-based on-set live color grading system that is powerful enough to allow concatenation of multiple 3D LUT and ASC CDL operators

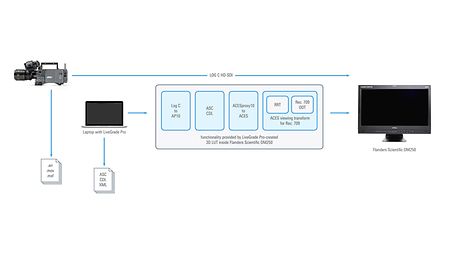

- Using a monitor with with 3D LUT support in conjunction with an ACES-savvy application that performs ASC CDL grading

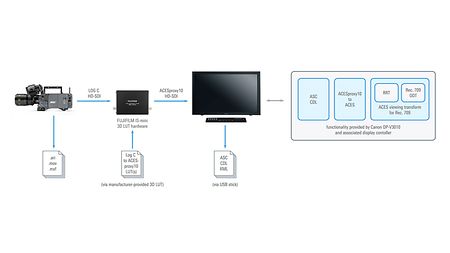

- Using an external 3D LUT box in conjunction with a monitor that accepts ACESproxy input and that internally performs ASC CDL grading

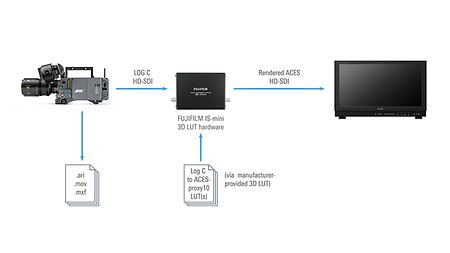

- Using an external 3D LUT box in conjunction with a standard monitor (foregoing any ASC CDL grading of the ACESproxy signal)

Grading with on-set live color grading systems

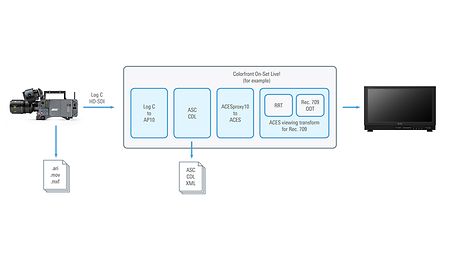

Highly configurable on-set live grading systems such as OSD Live! from Colorfront or Daylight from Filmlight can be set up to take a live Log C input signal, convert it to an ACESproxy signal, optionally apply ASC CDL grading operations to that signal, convert that (possibly modified) ACESproxy signal back to an ACES signal and finally apply the ACES output transform. Diagramatically this is shown in the figure below: